2007

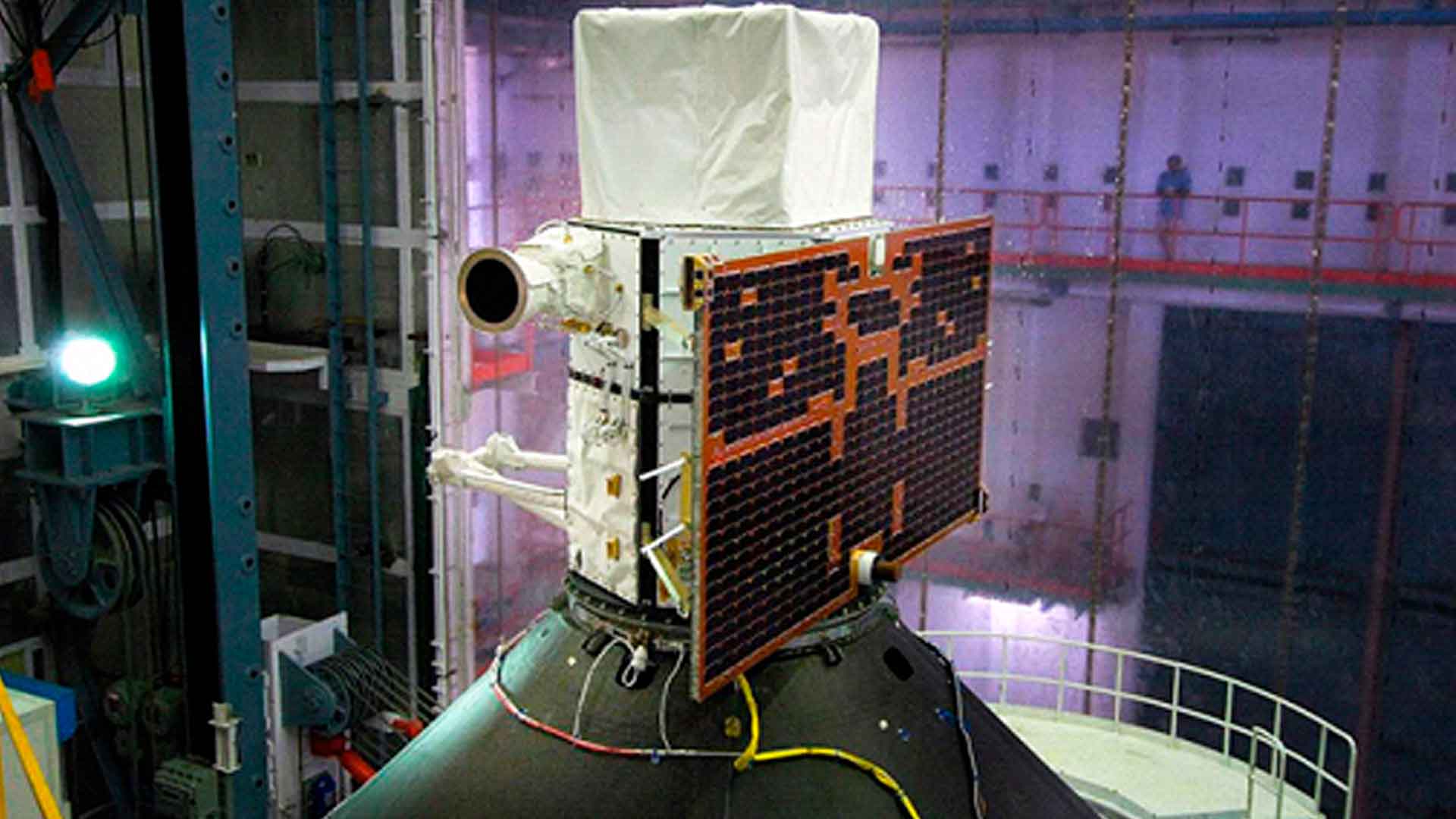

In 2007, we provided our thermal blankets to the Italian space agency for the Agile mission, designed to detect gamma-ray sources in the universe.

We develop spaceflight equipment for satellites and launchers. We have flight heritage on thermal control systems, structural panels, earth observation cameras, hold down and release mechanisms and actuators, and custom rad-hard microelectronics for space applications.

In 2023, we opened a new factory to integrate satellites. We are currently developing our own 500W bus perfectly suited for constellations.

Since our inception almost two decades ago, ARQUIMEA has contributed to both scientific missions (NASA, ESA…) and commercial missions (Hispasat, Beetlesat). We have participated in over 180 space missions and collaborated with more than 200 customers.

Several NASA Mars rovers include technologies supplied by ARQUIMEA.

Our offer for space ranges from flight-proven components such as optical payloads (cameras and video systems), hold down and release mechanism and actuators (HDRMs), pipes or rad-hard integrated circuits, to complete satellites. Our products are constantly evolving to anticipate the needs of our customers in future missions.

We are working on Artemis, the flagship program at NASA that will return humans to the moon.

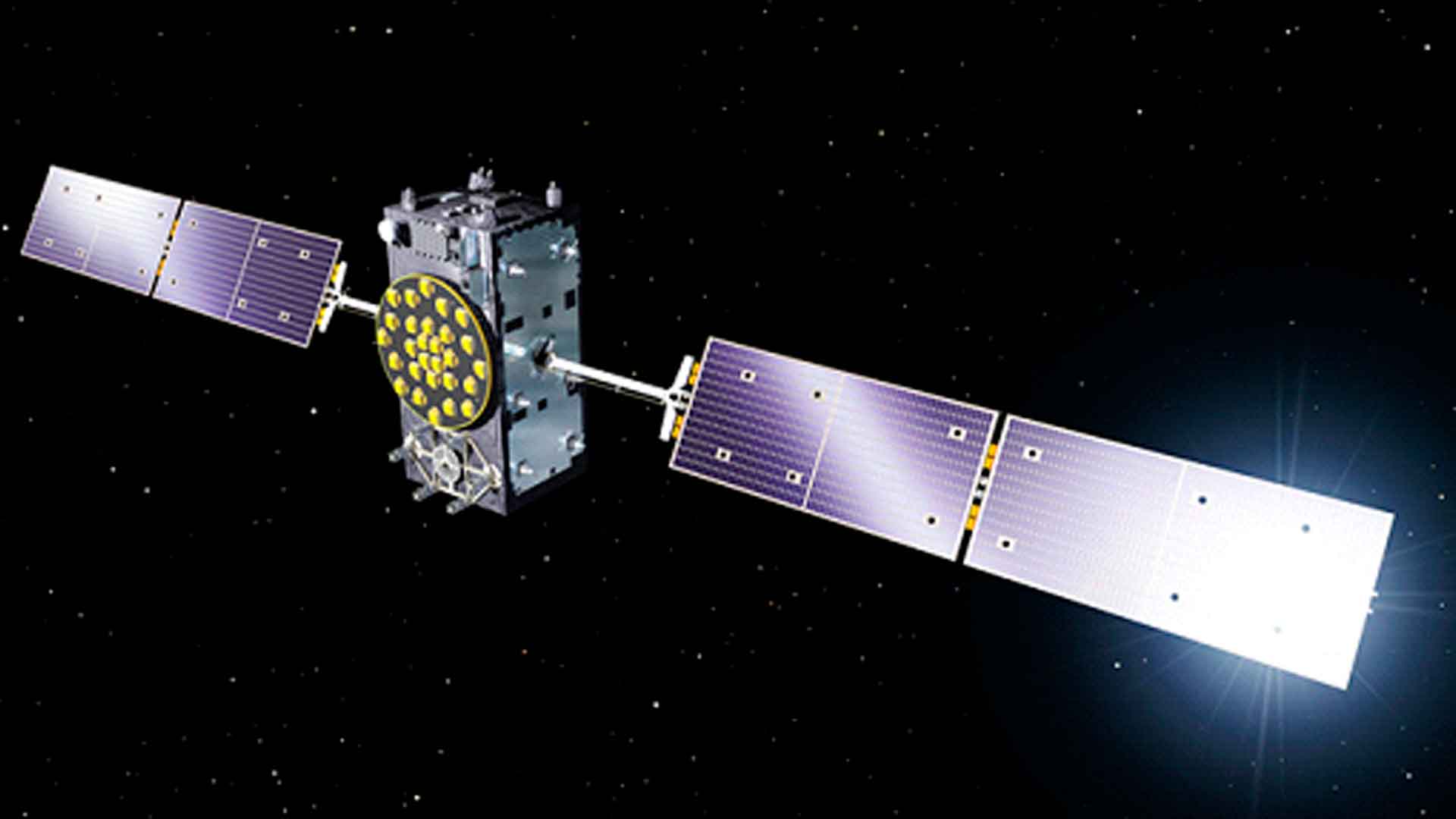

We are currently working on the development and mass production of small sats (<200Kg) for the BeetleSat constellation. BeetleSat is a LEO constellation offering global Ka-band connectivity for secure point-to-point communications, cellular backhaul, mobility and additional premium services, in the commercial and government sectors.

In 2007, we provided our thermal blankets to the Italian space agency for the Agile mission, designed to detect gamma-ray sources in the universe.

The Spanish satellite Hispasat 1E was successfully launched in 2010 accompanied by our thermal crew platform, which was key to the success of this mission.

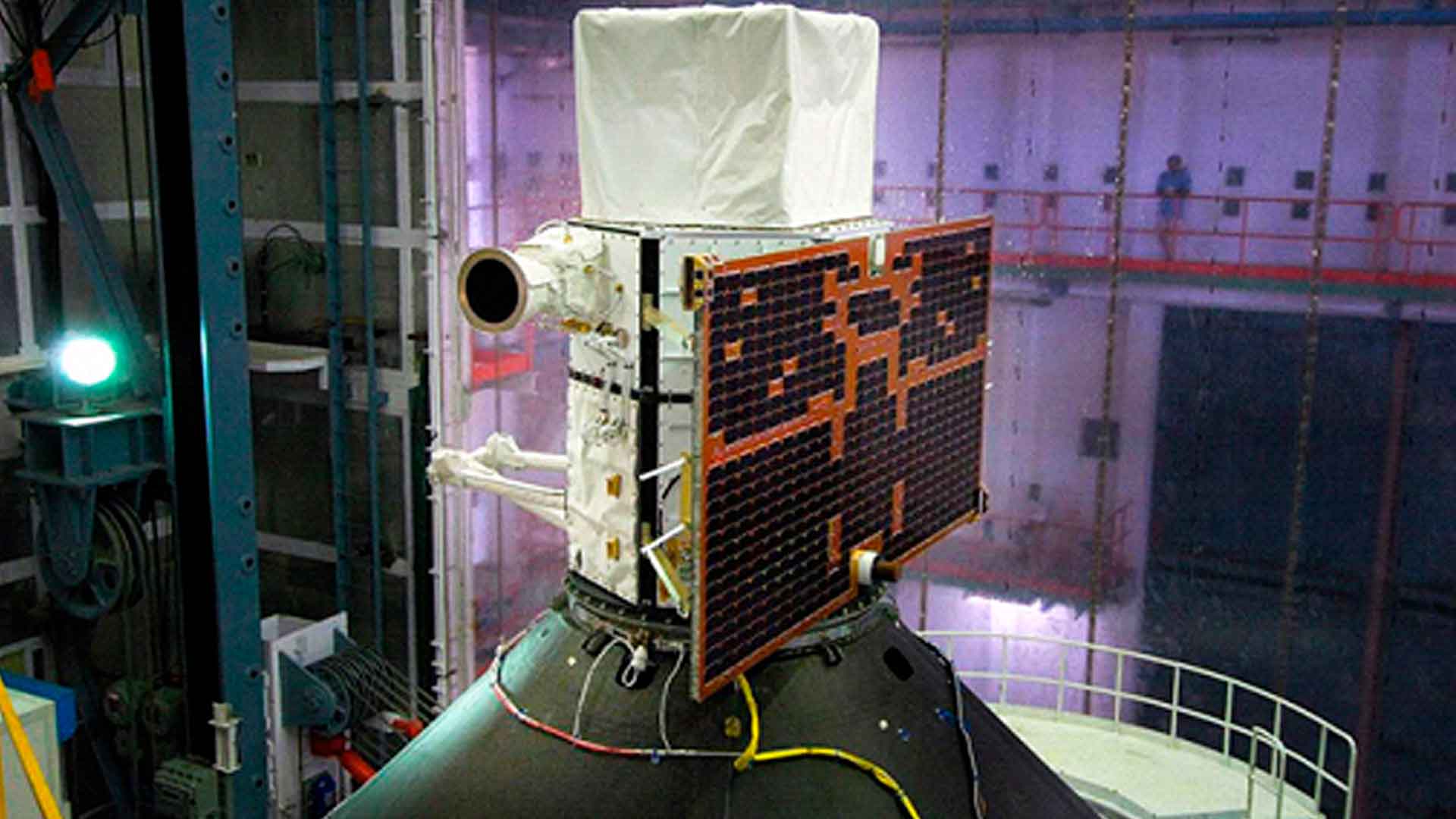

This project was designed to detect dark matter particles in cosmic rays.

Since its launch, AMS-02 has collected and analyzed billions of cosmic ray events.

In 2012, the satellite, built by the American company Space Systems, was put into orbit with the aim of offering TV, voice and data services to part of the United States, Asia and Oceania until 2027, where our loop heat pipes are located.

Qualified as Europe’s largest and most sophisticated telecommunications satellite, Alphasat was launched into orbit in 2013, equipped with our optimal thermal communications hardware.

In 2013 the Eutelsat 25b satellite was launched into orbit to provide television broadcast, business communications and data services over the Middle East , North Africa and Central Asia for 15 years.

The satellite, successfully launched by Spacex, has 24 Ku-band transponders and will provide communications services to China, India, the Middle East and Southeast Asia until 2028.

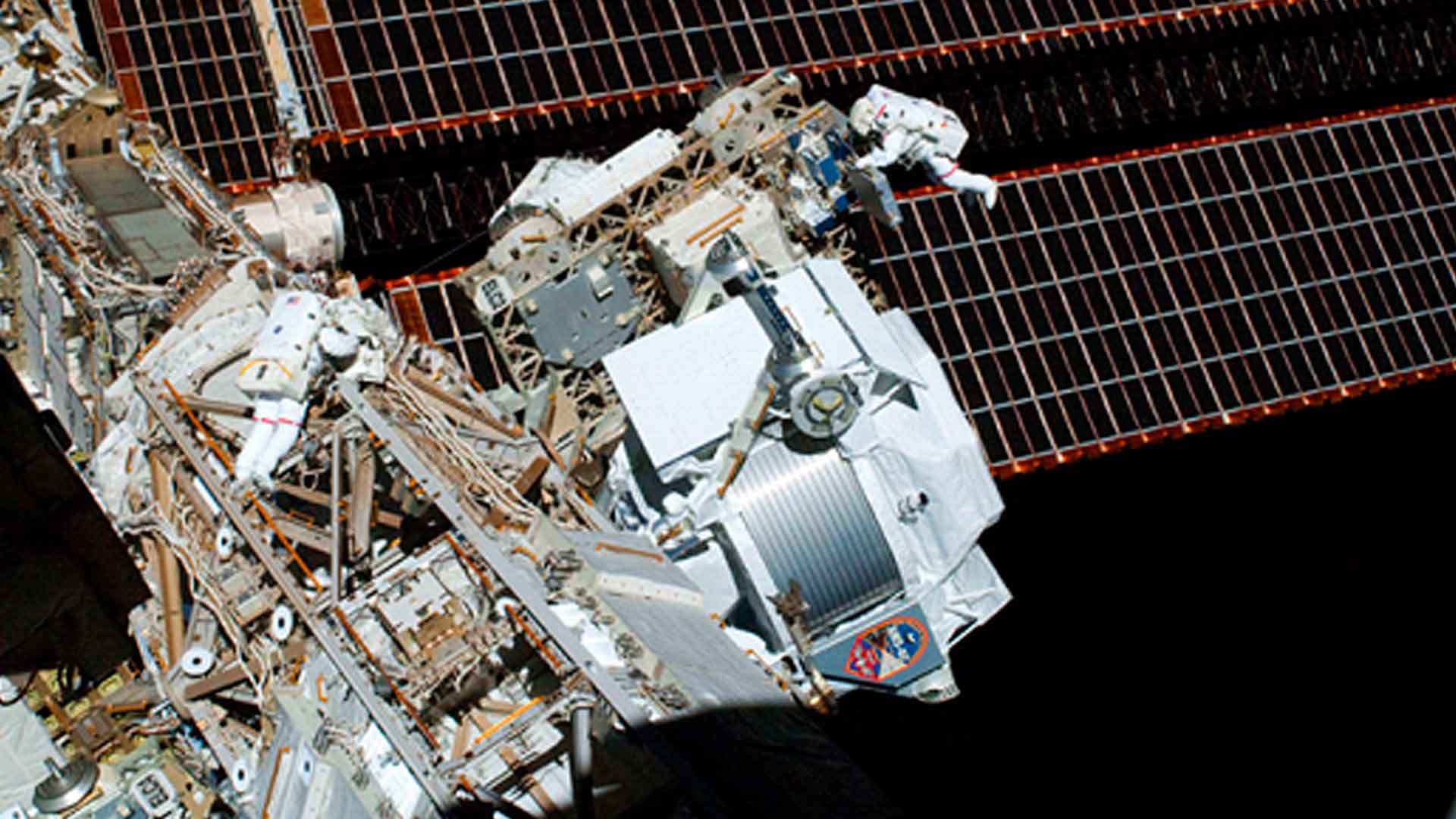

In August 2014, our cutting-edge technology, including radiators, heat pipes and slis, was an essential part of the success of the Galileo space mission, which is still active today, with the help of our components.

The first of the two satellites of the European Commission’s program has been providing terrestrial images of our vegetation, water and coastal areas, among others, useful information for agricultural and forestry practices for more than 8 years.

The c4, which is part of América móvil’s third generation of satellites, offers television, radio, data transmission and Internet solutions.

The satellite provides broadband services to remote and rural areas of Australia. Our heat pipes are still on board the satellite, which continues to operate today.

The novel laser communications system allows earth observation satellites to send large volumes of data almost instantaneously to the earth’s surface.

With our heat pipes and thermal blankets since 2016, Sentinel 3A has succeeded in its space-based ground monitoring mission since 2016.

Our loop heat pipes were key to the successful launch of Astro-H in February 2016, enabling accurate astronomical observations and meeting scientific objectives.

Since its launch, Sentinel 1B has relied on our efficient loop heat pipes and heat pipes. These components have been instrumental in maintaining thermal control and ensuring optimal mission performance.

Thanks to our thermostructural panels, Intelsat 31 succeeded in its launch in June 2016, providing reliable communication services from space.

These components provided a robust structure and efficient thermal control for the mission, ensuring optimal satellite performance and its ability to meet its communication objectives from space.

Our loop heat pipes ensured efficient thermal control for the mission, enabling optimal satellite performance and its ability to provide reliable communication services from space.

Since 2016, the heat pipes have been instrumental in the success of the Sky muster 2 mission, ensuring optimal thermal control for its communication services from space.

Since 2016, our radiators, heat pipes and thermal insulators have been vital in the success of the Galileo 15, 16, 17 and 18 missions, ensuring optimal thermal control from space.

Since December 2016, our thermostructural panels have been key to the success of the Echostar 19/Jupiter 2 mission, the satellite services Canada, USA and Mexico.

These components ensured efficient thermal control, enabling optimal satellite performance and its ability to provide advanced communication services.

Since its launch on January 27, 2017, Hispasat 36w-1 has featured our advanced thermal control technology, including psa systems, loop heat pipes and heat pipes.

Our panels have provided an essential structure for the satellite, enabling it to provide high-performance communication services from space.

Since its launch on July 23, 2017, our LHPS system has been instrumental in the success of the Bulgariasat-1 mission.

Our components provided a strong and reliable structure for the satellite, ensuring its optimal performance and its ability to provide communication services.

Since its launch in September 2017, our thermostructural panels and LHPS have been instrumental in asiasat 9, ensuring optimal performance and advanced communication services from space.

These components provided a strong and reliable structure for the satellite, ensuring its optimal performance and its ability to provide advanced communication services from space.

Our panels provide a robust and reliable structure for the satellite, which continues to operate since 2017, substantially improving the overall availability of navigation signals.

Cheops will study already known extrasolar planets to evaluate their mass, density, composition and formation. ARQUIMEA has contributed to the mission with the fabrication and integration of all the MLI (Multilayer Insulation Films) or thermal blankets of the platform that cover the satellite, to reduce the loss of heat by thermal radiation.

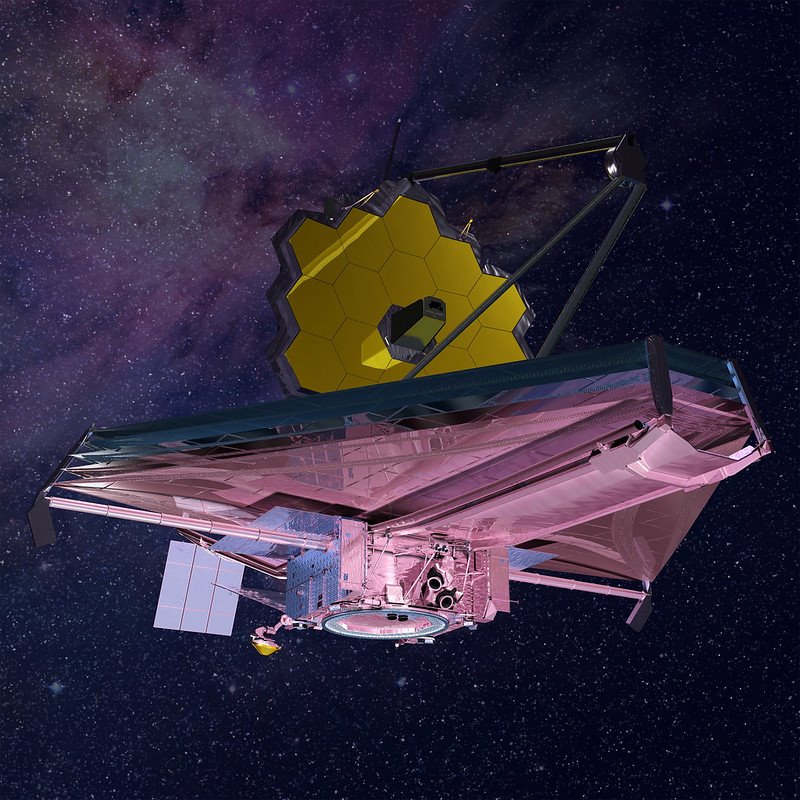

We contributed to this mission by manufacturing single-layer cryogenic insulating sheaths that are part of the thermal control system of the near-infrared spectrograph (NIRSpec instrument). Europe’s contribution to the mission will provide a deeper insight into the evolution of the universe.

ARQUIMEA is present in 19 Copernicus missions in which we have manufactured structures, systems and thermal hardware for about 20 satellites and instruments. In addition, we have designed and manufactured mechanisms and actuators for the deployable system of the LEA antenna.

Euclid was successfully launched and has five heat pipes for the thermal control of the satellite that contribute to its correct operation. The objective of this mission is to perform a three-dimensional mapping of large-scale structures, making it the most complete map of the universe to date.

Also successfully launched was Psyche, which has thermostructural panels with embedded heat pipes. This exciting NASA mission called Psyche is an orbital mission, to explore the origin of planetary cores by studying the metallic asteroid.

Contact us, set us a challenge and discover everything we can offer you.